Manufacturing Capabilities

State-of-the-art production equipment and integrated manufacturing services

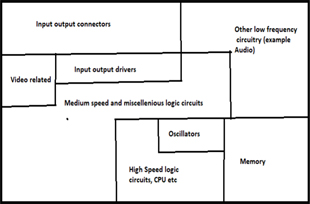

PCB Assembly (PCBA)

High-quality PCB assembly services using advanced SMT and through-hole technology with rigorous quality control processes.

- Surface Mount Technology (SMT)

- Through-hole assembly

- Mixed technology assembly

- Fine pitch components

- BGA & microBGA assembly

Box Building & Integration

Complete electro-mechanical assembly services including enclosure assembly, cable harnessing, and final product integration.

- Enclosure assembly

- Cable & wire harnessing

- Mechanical assembly

- System integration

- Final product assembly

Testing & Quality Control

Comprehensive testing procedures including functional testing, burn-in testing, and quality assurance protocols.

- In-circuit testing (ICT)

- Functional testing

- Burn-in testing

- Environmental testing

- Quality certifications

Product Development Support

Design for manufacturing (DFM) consultation, prototyping support, and manufacturing optimization services.

- Design for manufacturing (DFM)

- Prototype development

- Manufacturing optimization

- Cost reduction analysis

- Supply chain management